TM 10-7360-206-13

0010 00

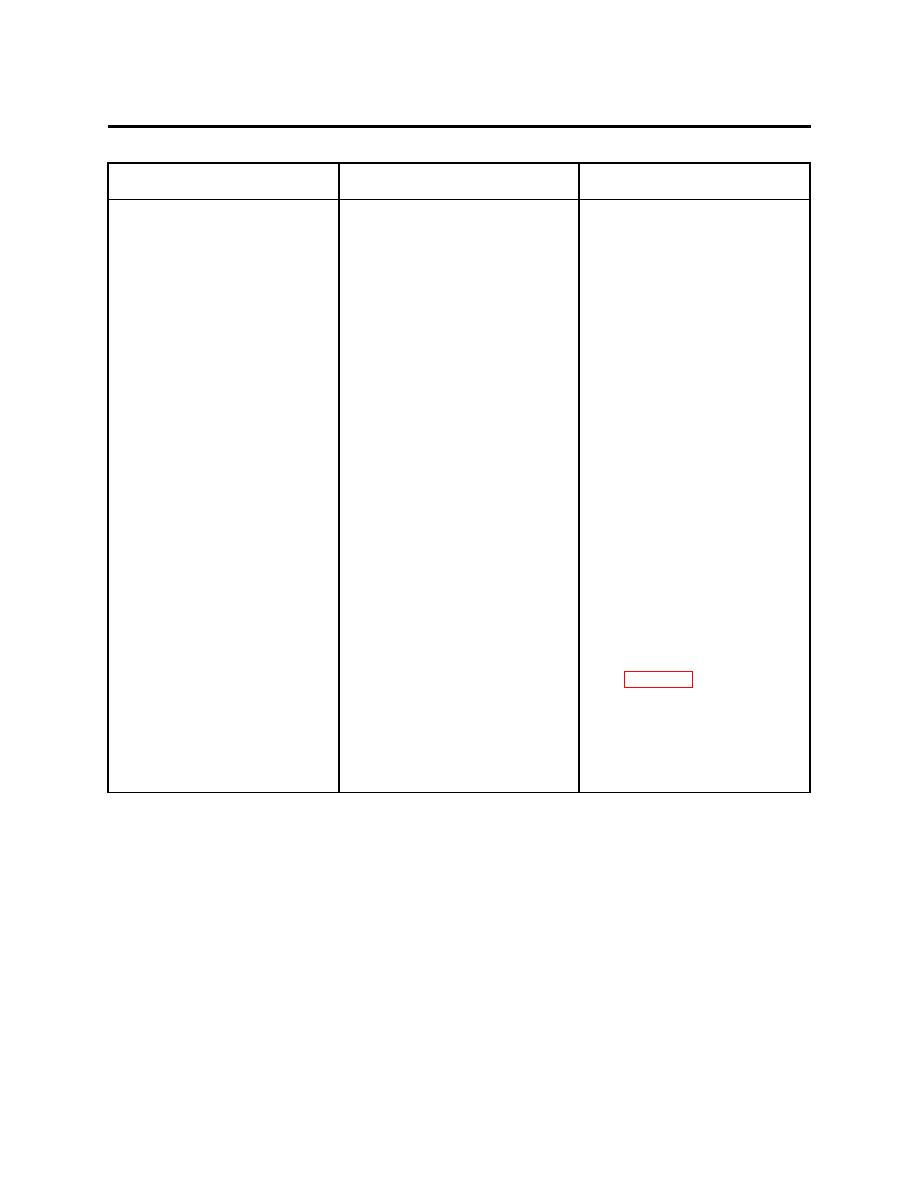

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

Drop leaf tables bind during

Functionally check.

Report to Direct Support

setup.

maintenance personnel.

Visual inspection.

If griddle is badly damaged

Griddle anodized surface worn

(50% on both surfaces), replace

off or badly scratched and

griddle.

warped.

Shock absorber leaking oil.

Visual inspection and lack of

Replace if inspection indicates

sufficient damping in transit.

excessive seal wear.

Replace defective components

Check to see if release pin detent

Leveling jack binding during

as authorized or refer to direct

balls are defective or if release

operation.

support maintenance personnel.

pins bind during removal.

Check to see If hinge pins are

Replace defective hinge pins or

Ramps bind or won't pivot

defective.

ramp assembly.

properly.

Visually check to see If bolt is

Remove with a punch, drift, or

Ramp latch bolt frozen or

bent.

saw as required and replace.

difficult to slide.

Tent pole and strut assembly

Check lubrication.

Clean and lube, if required. If

binds.

still inoperable, replace.

Corner post latches fail to latch.

Check lubrication of mechanism.

Lube, if required. If still

inoperable, replace.

Corner post binds.

Check lubrication.

Clean and lube, if required. If

still inoperable, replace.

Component( s) loose or too dirty

Visual inspection.

Clean and tighten as applicable

to function properly.

(refer WP 0010).

Insulated liquid dispenser faucet

Visual inspection.

Repair faucet assembly.

leaking.

Replace worn or dull blades.

Visual inspection and check

Mounted can opener cutting

If still inoperable, replace.

operation.

blades worn or dull.

END OF WORK PACKAGE

0010 00-2