TM 10-7310-282-10

0027 00

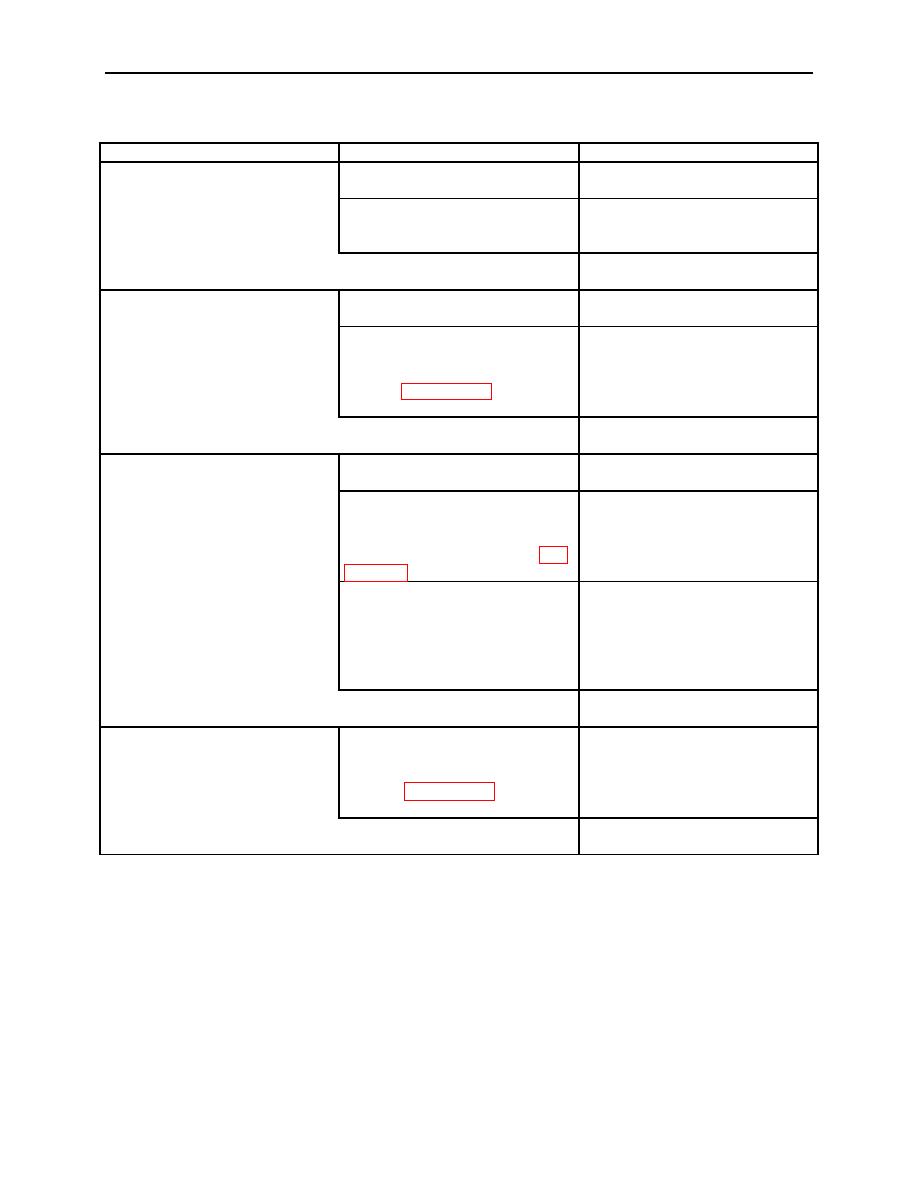

Table 2. Mechanically Cooled Beverage Dispenser Troubleshooting Procedures.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. No Power

Step 1. Check settings at control

Switches should be ON.

switches.

Step 2. Check that all external

Establish or reestablish power

power connections have been

connections. Consult with

made.

facilities electricians if necessary.

If condition persists, notify unit

maintenance.

2. Does Not Agitate

Step 1. Check settings at control

Switches should be ON.

switches.

Dispose of beverage batch, clean

Step 2. Inspect pump cover and

dispenser, and start new batch.

impeller for obstructions, such as

Ensure that powdered drink mix

undiluted powdered drink mix.

is thoroughly diluted into water

Refer to WP 0008 00. "Cleaning".

before turning agitator ON.

If condition persists, notify unit

maintenance.

3. Does Not Cool

Step 1. Check settings at control

Switches should be ON.

switches.

Dispose of beverage batch, clean

Step 2. Inspect pump cover,

dispenser, and start new batch.

impeller, and cooling coil for

Ensure that powdered drink mix

obstructions, such as undiluted

is thoroughly diluted into water

powdered drink mix. Refer to WP

before turning agitator ON.

0008 00, "Cleaning".

Step 3. Inspect dispenser

Remove obstructions, and ensure

location for obstructions to

that there is at least 6 inches of

cooling louvers.

clearance around the chassis of

the dispenser. Turn Cooling

Switch OFF, wait 15 minutes, and

turn Cooling Switch ON.

If condition persists, notify unit

maintenance.

Dispose of beverage batch, clean

4. Does Not Dispense

Inspect valve or pinch tube, as

dispenser, and start new batch.

applicable, for obstructions, such

Ensure that powdered drink mix

as undiluted powdered drink mix.

is thoroughly diluted into water

Refer to WP 0008 00,

before turning agitator ON.

"Cleaning".

If condition persists, notify unit

maintenance.

0027 00-3